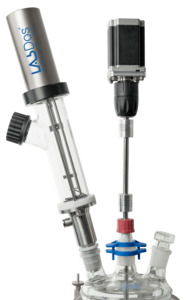

LabDos® Solid-SC Cellular Sluice Conveyors

for Powders, Granulates, Crystals...

The LabDos® Solid-SC sold matter dosing device is suited for the dosing of solid matter in powder and granulate form.

The manual addition of solid reactants to a schedule or the setting of a pH value by the addition of solid matter is a time-consuming and potentially volatile operation for a laboratory worker.

You can now also automate these working operations by using LabDos® Solid-SC. It is also ideally suited to the automatic inoculation of crystallization processes.

LabDos® Solid-SC fits ideally into the structure of a reactor thanks to its slim construction and can be directly operated via a PFM (pulse frequency modulation) digital output of a LabManager®.

Independent operation is possible with the use of the special LabDos® Solid control unit IF-P-SOLID-SC-ST.

Advantages of the Cellular Sluice Conveyor

- Resistant against most chemicals

- Suited for powder and granulate dosing.

- Large dosing rate range

- A new form of mechanical

- Gravimetric dosing possible in combination with GraviDos®

- Dosing of solid matter

- pH value control with solid matter

- Inoculation of crystallization processes

- Very low space requirement, extremely easy assembly

- May be fully dismantled for cleaning

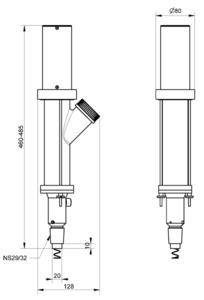

| Dimensions | approx. 130 x 500 x 80 mm |

|---|---|

| Connection | NS29/32 |

| Housing material | Borosilicate glass, polyoxymethylene (POM), V4A stainless steel |

| Weight approx. | 1,300 g |

| Dosing tank (maximum dosing quantity) | 200 cm³, approx. 2,200 cm³ with optional refilling tank |

| Control (IS-SOLIDOS2-x) | 24 V impulse, pulse duration 200 ms |

| Power supply | 24 V DC, 1 A |

| Scope of delivery | Dosing device with 1.5 m connecting cable for an active digital output of a LabManager® AS or standalonecontrol unit, as an option also connecting cable for LabManager® Classic or LabBox® AS |

LabDos® Solid Control Device for Stand-Alone Operation

The LabDos® Solid control unit provides the functions which are best for the operation of the LabDos® Solid dosing devices.

The device can be controlled both manually via the film keyboard and via a serial (optional) or analogue interface. This compact device can be used everywhere even without an automation system due to its five dosing modes.

| Product Code | Description |

|---|---|

| IF-P-SOLID-SC-x | Solid matter dosing device, basic unit for LabManager® |

| IF-P-SOLID-SC-x-ST | Solid matter dosing device, basic unit for stand-alone controller |

| IF-P-SOLID-SC-SK-x | LabDos® Solid-SC lock chamber |

| IF-P-SOLID-SC-HEIZ | Electric heating element for the heating of the connecting piece for the prevention of condensation |

| IF-P-SOLID-SC-KF | Cold trap against condensation in the connecting piece, NS29/32 |

| IF-P-SOLID-SC-IN | Inerting connection for LabDos® Solid-SC solid matter dosing device on the drive |

| IF-P-SOLID-SC-NB | LabDos® Solid-SC refilling tank, 2,000 cm³ |

| IF-P-SOLID-SC- HC4 | Option of metal parts in contact with the medium in Hastelloy |

Models

| x=Model | -12 | -25 | -50 | -100 | -200 | -400 |

|---|---|---|---|---|---|---|

| Dosing rate approx. cm³/min) | 12 | 25 | 50 | 100 | 200 | 400 |

| Dosing quantity approx. (cm³) | 0,12 | 0,25 | 0,50 | 1 | 2 | 4 |