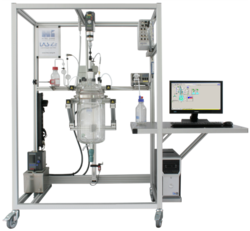

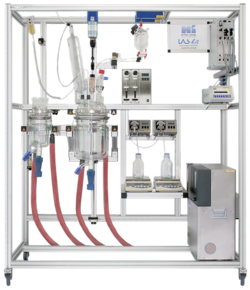

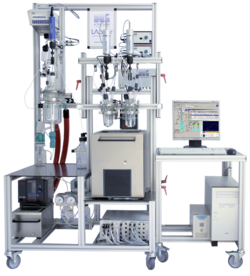

Laboratory Reactor Systems for every Application

HiTec Zang offers a sophisticated range of reactor systems in scale from mL to 100 L for the development laboratory, safety laboratory, kilo laboratory, pilot plant, miniplant and the small-volume production.

The fully automated plants are employed in the fields of chemistry, pharmaceuticals, biotechnology and foodstuffs technology for:

- Product development

- Process development

- Process optimization

- Safety investigations

- Training purposes

- and scale-up Applications

The Advantages

- Optimally tailored to your requirements

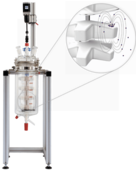

- Space-saving construction

- Electrically lowerable reactor vessel

- Optimal use of laboratory capacity through 24h operation

- Best possible quality and reproducibility

- Remote maintenance

The Possibilities

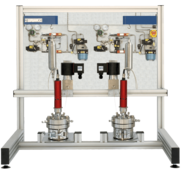

- Fixed-bed Reactor

- Temperature regulation

- Pressure and vacuum regulation

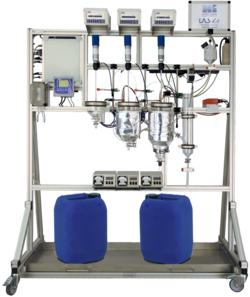

- Dosing of liquids, gravimetrically, with pumps or by gas pressure via valves

- Stirrer speed control, torque recoding

- pH regulation alkaline and/or acidic

- Rectification, distillation and reflux distillation

- Multi-stage synthesis

- Phase separation

- Batch control in accordance with the NAMUR basic operation concept

- Reaction calorimetry

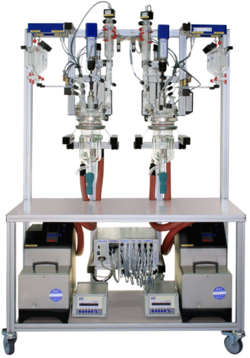

- Coupled multiple-reactor systems

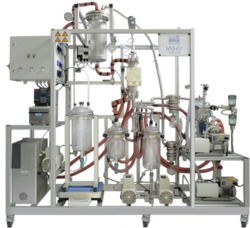

- Mini-plants

- Plants for training

On the following subpages you will find further information on our laboratory reactor systems and on potential features and applications.