HiClave™ High Pressure Process Plant

HiClave™ high-pressure reactor systems are a proven solution for high-pressure reactions, especially on multi-phase systems.

They may be supplied in a volume range of 10 to 250 ml, with a maximum pressure of up to 300 bar and a maximum temperature of up to 300 °C. Thanks to the pure metallic pressure cap seal, the system achieves a tightness which enables highly accurate measurements of gas consumption. Up to 7 media connections are possible.

For reactors of 100 ml content and larger the connections may be partially or fully routed around the outside of the cover flange.

This enables better handling and creates more space for peripherals. Various heating/cooling systems, magnetic stirrers or magnet-coupled overhead stirrers and varied forms of gas and liquid supply systems are available.

They may be operated as single and parallel reactor systems. In addition to the standard configurations, you can have systems manufactured especially to suit your demands.

The Advantages of HiClave™

- Directly sealing cover

- Open, expandable system

- Simple handling

- Cooling option

Suited for the Following Processes

- Hydrogenation

- Oxidation

- Carbonylation

- Polymerization

- And many more

Standard Systems

HiClave™ systems are built up in a modular manner. The components described below form the basis for versatile pressure reaction systems. They can be adjusted to suit the demands in each case and upgraded with the aid of the auxiliary modules and components.

10 ml and 20 ml Reactors

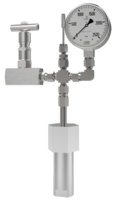

10 ml and 20 ml reactors have a cover with a union nut and a central media connection with a crosspiece. The centre connection of the crosspiece is occupied by the interior temperature controller, those at the side normally with the media connection and manometer.

The reactors are tempered using a magnetic heating stirrer with a heating block and stirred using a magnetic stirring rod.

Equipment

- Simple heating and stirring using a magnetic heating stirrer with a heating block attachment

- Temperature controller (Pt100)

Possible Connections

- 1 x temperature controller

- 1 x pressure display

- 1 x media connection

50 ml Reactor

The 50 ml reactor has a cover with a union nut and 3 connections. One of these can be fitted with a magnet-coupled stirrer drive. The stirrer runs eccentrically. The two other connections are used for the thermal controller and media supply. If a magnetic stirrer is preferred to a stirrer drive, the connection which is thus freed may be used as desired.

The reactors are heated using a heating sleeve and stirred from above. In such a case cooling may be carried out using a cooling plate. Alternatively, heating and stirring takes place using a magnetic heating stirrer and a heating block.

Equipment

- Heating via a heating sleeve

- Stirring using a magnetic stirrer head

- Temperature controller (Pt100)

Connection Pieces

- 1 x temperature controller

- 1 x overhead stirrer, alternatively free

- 1 x media connection

Options

- Cooling plate for controlled cooling

- Other connection allocations

- A heating block or heating sleeve

100...250 ml Reactor

The 100 ml to 250 ml reactors have a flange cover which is screwed down using expansion screws with 7 connections. Three of these connections have been moved to the outer side of the cover so that they may be better reached.

The central connecting piece is occupied by the magnet-coupled stirring head. The reactor may be manufactured in stainless steel 1.4571 (SS 316Tl) or Hastelloy.

The reactors are heated using a heating sleeve and can be cooled either via a cooling plate or an internal cooling loop. Stirring takes place using a magnetic stirrer head, optionally with a maximum torque of 20 Ncm or 50 Ncm. The appropriate fitting kits may be supplied either in stainless steel 1.4571 (SS 316Tl) or in Hastelloy C4.

Options

- Hydration/gas injection module

- Liquid and/or gas sampling

- Cooling via a cooling plate or a cooling loop

- Hastelloy finish

Possible Connections

- 1 x immersion pipe for temperature controller

- 1 x stirrer

- 1 x metal rupture disk for safe limitation of the maximum pressure

- 1 x pressure display

- 1 x valve for pressure relief

- 2 x freely allocatable, e. g. for a gas sampling valve or liquid sampling

Hydration module

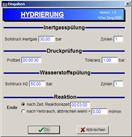

The VL-HICLAVE-HYDR hydration module enables a complete hydration process to be carried out including inert gas rinsing and leak testing of the reactor without any manual Intervention. As a result, no-one has to be present in the high-risk area during the time in which the reactor is under pressure. For this, inert gas is applied to the reactor up to an adjustable pressure and then aerated. This rinsing cycle may be repeated as often as desired. Subsequently, a pressure check with inert gas is performed. The duration of the check and the tolerance for passing the test are freely selectable.

Only if the pressure test has been passed is the reaction gas – in the above example hydrogen is released, otherwise the reactor is aerated. Then, rinsing is made with the reaction gas, the set pressure is reached and the process started.

A gas consumption measurement unit for the recording of kinetic data is integrated. The gas consumption may also be used as a criterion for aborting, meaning that the reaction will be aborted if consumption has fallen below a given rate.

The system is monitored and operated using a generally self-explanatory user interface.

The measured data are automatically recorded and listed in a report. If a gas consumption measurement has been carried out, a kinetic analysis of the consumption curve may also be performed.

| Frame | Square anodised aluminium profile, stainless steel platform for the reactor |

|---|---|

| Reactor | 10…250 ml stainless steel reactor (optionally in Hastelloy), 300 bar, 300 °C, optionally 450 °C, rupture disk |

| Stirrer | Stirrer with magnetic coupling, speed 200…1.500 rpm, maximum torque 20/50 Ncm, including an analogue interface for the speed control (reactors ≥ 50 ml) Or: Magnetic heating stirrer with a heating block and magnetic stirring rod (Reactors ≤ 50 ml) |

| Heating/cooling system | Heating sleeve/cooling plate (alternatively a cooling loop), working temperature range 40…350 °C in the jacket, heating power up to 700 W Alternative: Magnetic heating stirrer with a heating block |

| Sampling | Sampling Manually |

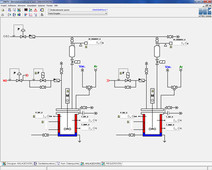

| Gas injection | Reaction gas under pressure regulation via MFC, including gas consumption measurement, by-pass valve |

| Inerting | Inert gas under pressure regulation, exhaust gas via a high-pressure solenoid valve |

| Dosing system, gravimetrically | GraviDos® high-pressure dosing system up to 300 bar, alternatively/optionally a high-pressure pump and balance |

| Sensors | Reactor interior temperature, jacket temperature, reactor interior pressure, speed, ATR-FTIR |

| Automation | Example of two autoclaves: LabManager® 2 with the following equipment: 4 Pt100 temperature measurement inputs, 4 analogue inputs (current and voltage), 4 RS232 interfaces (stirrer, hydration modules), 4 GraviDos® connections, 8 digital outputs 2 safety temperature controllers HiTec Zang OS, TFT monitor, uninterrupted power supply and a UPS management system, LabVision® software package with project module library and EasyBatch™ This automation system can monitor 2 reactors, an expansion to 4 reactors is possible |

| Materials | Mainly stainless steel 1.4571, other types of stainless steel, Hastelloy |

| Product Code | Description |

|---|---|

| VL-HICLAVE-SC-n | HiClave™ Frame for HiClave™ pressure reactors, tubing, cabling, pressure sensors |

| VL-HICLAVE-ws-vol | HiClave™ pressure reactor, manometer, Pt100 temperature sensor, rupture disk |

| VL-HICLAVE-HEABAN-vol | Heating sleeve, 230 V AC 500 W, double temperature sensor, thermal protector |

| VL-HICLAVE-COOLP | Cooling plate for mains water or thermostat connection, with 24 V solenoid valve |

| VL-HICLAVE-STIRR-20 | Magnet-coupled overhead stirrer, 20 Ncm |

| VL-HICLAVE-STIRR-50 | Magnet-coupled overhead stirrer, 50 Ncm |

n ( = Number of reactors): 1 bis 8

ws ( = material): Stainless steel 1.4571 (SS 316Tl): e, Hastelloy C4: h, special material: s

vol ( =working capacity): 10, 20, 50, 100, 150, 250 equivalent 10, 20, 50, 100, 150 or 250 ml

![HiClave™ 200 ml double-reactor system with regulated gas injection [Translate to English:] HiClave™ 200 ml-Doppelreaktorsystem mit geregelter Begasung](/fileadmin/processed_files_storage_/1/4/csm_002001_hiclave_250_ml_anlage_mit_monitor_low_8a8c4fbda3.png)

![HiClave™ - RI Flow Chart [Translate to English:] HiClave™ - RI-Fließbild](/fileadmin/processed_files_storage_/d/1/csm_HiClave-RI-Fliessbild_d36f4b956b.jpg)